Our Products

Brazing with Silver-Copper-Phosphorus and Copper Phosphorus alloys is widely used for the joining of Copper to Copper where the absence of a flux is a major benefit. The self-fluxing action of the Phosphorus ensures that flux entrapment problems are largely avoided and that high standards of joint soundness can be maintained.

Brazing with Silver-Copper-Phosphorus and Copper Phosphorus alloys is widely used for the joining of Copper to Copper where the absence of a flux is a major benefit. The self-fluxing action of the Phosphorus ensures that flux entrapment problems are largely avoided and that high standards of joint soundness can be maintained.

High phosphorus levels give excellent capillary penetration since the fluidity of the molten brazing alloy is controlled by the Phosphorus content Alloys with high phosphorus content are less ductile than those with lower Phosphorus and higher Silver contents.

For applications where optimum mechanical strength, or resistance to vibration, is required the lower Phosphorus alloys are necessary (ie Phos 5, Phos 2, Phos 0R). The tin-containing alloy, Phos 0T, offers controlled fluidity, a low melting point and joints of good appearance. Phosphorus containing alloys should not be used on Ferrous or Nickel based parent alloys as they will result in brittle joints. This family of alloys can also be used for brazing high copper content alloys, providing that a suitable flux is used. Phos 15 is available in Strip form for the brazing of Electrical contact material.

| Thessco Grade | ISO 17672:2016 | Nominal Composition (%) | Melting Range (°C) | ||||

|---|---|---|---|---|---|---|---|

| Silver | Copper | Phos | Other | Solidus | Liquidus | ||

| Phos 15 | CuP 284 | 15 | 80 | 5 | 645 | 800 | |

| Phos 5 | CuP 281 | 5 | 89 | 6 | 645 | 815 | |

| Phos 2 | CuP 279 | 2 | 91.7 | 6.3 | 710 | 825 | |

| Phos 0 | CuP 182 | 92.2 | 7.8 | 710 | 770 | ||

| Phos 0L | CuP 180 | 93 | 7 | 710 | 820 | ||

| Phos 0R | CuP 179 | 93.8 | 6.2 | 710 | 890 | ||

Available in – Rods & Wire – 1mm to 5mm. Strip & Foil – from 0.08mm to 3mm thickness.

Other Alloys are available subject to customer requirement.

Safety Data Sheets are available on request. Printing on rods is also available –subject to customers’ requirements.

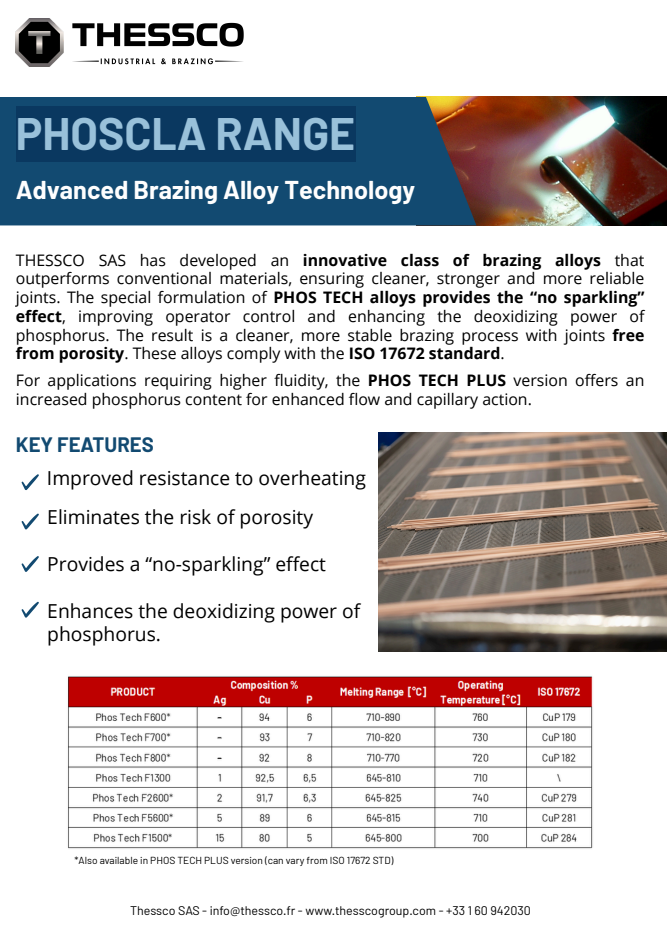

Introducing the PHOSCLA Brazing Range

THESSCO has developed an innovative class of brazing alloys that outperforms conventional materials, ensuring cleaner, stronger and more reliable joints.

THESSCO has developed an innovative class of brazing alloys that outperforms conventional materials, ensuring cleaner, stronger and more reliable joints.

The special formulation of PHOS TECH alloys provides the “no sparkling” effect, improving operator control and enhancing the deoxidizing power of phosphorus. The result is a cleaner, more stable brazing process with joints free from porosity. These alloys comply with the ISO 17672 standard.

For applications requiring higher fluidity, the PHOS TECH PLUS version offers an increased phosphorus content for enhanced flow and capillary action.

PHOSCLA KEY FEATURES

-

Improved resistance to overheating

-

Eliminates the risk of porosity

-

Provides a “no-sparkling” effect

-

Enhances the deoxidizing power of phosphorus

For more information, please refer to our latest PHOSCLA brochure or contact us directly.

| Product | ISO 17672 | Composition (%) | Melting Range (°C) | Operating Temperature(°C) | ||||

|---|---|---|---|---|---|---|---|---|

| Ag | Cu | P | ||||||

| Phos Tech F600* | CuP 179 | - | 94 | 6 | 710 - 890 | 760 | ||

| Phos Tech F700* | CuP 180 | - | 93 | 7 | 710 - 820 | 730 | ||

| Phos Tech F800* | CuP 182 | - | 92 | 8 | 710 - 770 | 720 | ||

| Phos Tech F1300 | - | 1 | 92.2 | 6.5 | 645 - 810 | 710 | ||

| Phos Tech F2600* | CuP 279 | 2 | 91.7 | 6.3 | 645 - 825 | 740 | ||

| Phos Tech F5600* | CuP 281 | 5 | 89 | 6 | 645 - 815 | 710 | ||

| Phos Tech F1500* | CuP 284 | 15 | 80 | 5 | 645 - 800 | 700 | ||

* Also available in PHOS TECH PLUS version (can vary from ISO 17672 STD)